- HOME

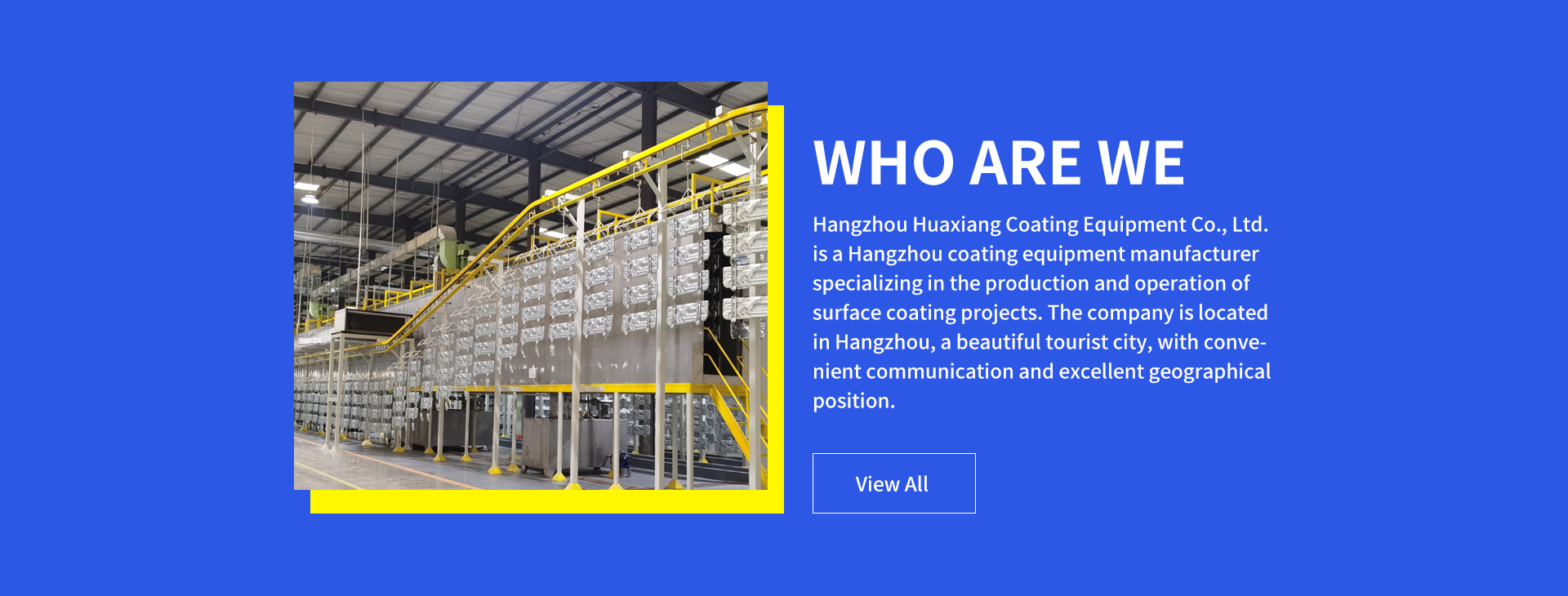

- ABOUT US

- PRODUCT

- CASE

- VIDEO

-

NEWS

Company News Industry News Powder Coating Machine Powder Coating Gun Manual Powder Coating Machine Powder Coating Spray Booth Powder Coating Curing Oven Electrostatic Liquid painting Powder Coating Line Automatic Powder Coating Line Powder Coating Line Suppliers Powder Coat Machine Powder Coat Kit Powder Coat Spray Gun Powder Coat Equipment Powder Coat Gun Powder Coating Gun Kit Powder Spraying Equipment Industrial Spraying Equipment Manual Spray Equipment Electrostatic Spray Equipment Automatic Spraying Equipment Powder Spray System Powder Spraying Booth Powder Spraying Line Powder Spraying Oven Powder Spraying Gun Electric Powder Spraying Oven

-

BLOG

Powder Coat Booth Industrial Powder Coat Booth Manual Powder Coating Booth ESD Powder Coating Booth Auto Powder Coating Booth Powder Coating Oven Industrial Powder Coating Oven Gas Powder Coating Oven ESD Powder Coating Oven Powder Coating Machine Industrial Powder Coat Machine Manual Powder Coat Machine ESD Powder Coat Machine

- Spray Machine

- CONTACT US